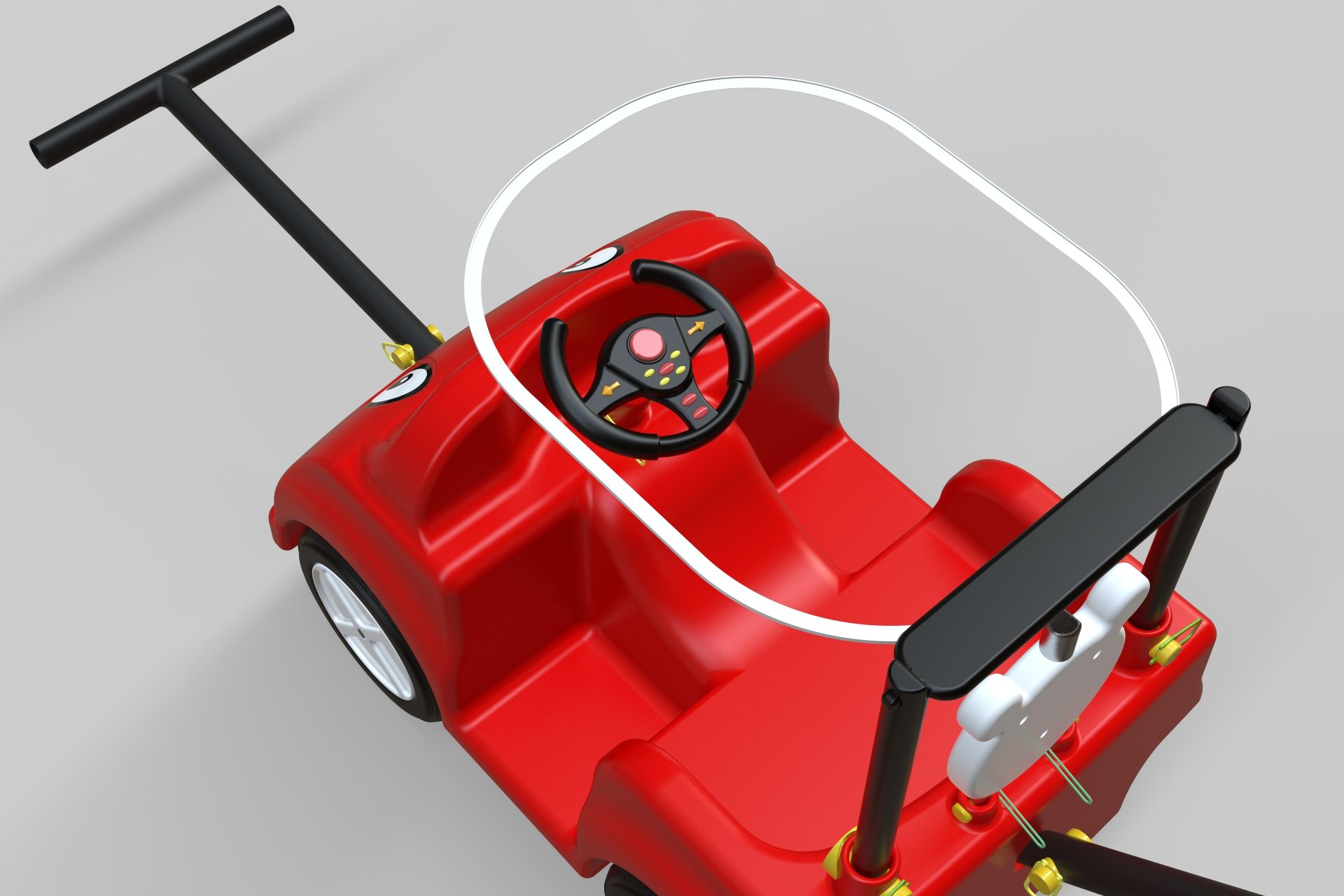

Next-Gen Kids Ride-On Car

Engineering joy with safety, durability, and manufacturing readiness at the core

Redesigned a child’s ride-on car from concept to production-ready 3D model, focusing on critical safety upgrades, enhanced durability, and seamless manufacturability.

The Safety & Durability Upgrade

- Child Safety First – Designed all edges, pinch points, and moving parts to exceed common toy safety standards (ASTM F963, EN 71).

- Enhanced Durability – Reinforced high-stress areas (steering column, axle mounts, canopy joints) for rigorous play.

- Simplified Assembly – Optimized part count and designed intuitive snap-fits and fasteners for easier, cheaper assembly.

- Ergonomic Comfort – Improved seat contour, handle grip, and canopy positioning for a child’s posture and comfort.

- Production-Ready 3D Model– Delivered in universally accepted formats (STEP, IGES) ready for tooling and injection molding.

Our Redesign Process

- Safety & Standards Audit – Reviewed the original model against ASTM F963 (US) and EN 71 (EU) toy safety standards.

- Structural & Ergonomics Analysis – Identified weak points and discomfort areas for targeted reinforcement and reshaping.

- Design for Manufacturing (DFM) – Redesigned components for injection molding, considering draft angles, wall thickness, and material flow.

- Final Integration & Documentation – Delivered clean 3D assemblies with a summary report of all safety and manufacturing improvements.

The Outcome

An automated plant that turns waste into revenue

- Safety-Certification Ready – Design adheres to ASTM F963 & EN 71 standards, streamlining approval.

- Reliable Performance – Intelligent layout ensures stable operation, protecting internal components and ensuring customer satisfaction.

- Durability Kids Can’t Break – Reinforced joints and structures built to withstand years of rough play.