Automated C&D Waste Recycling Plant

Engineering efficiency into construction waste processing.

Designed a fully automated sorting and conveying system that transforms mixed demolition debris into high-value, clean aggregate—boosting throughput, safety, and product consistency.

The Engineered System

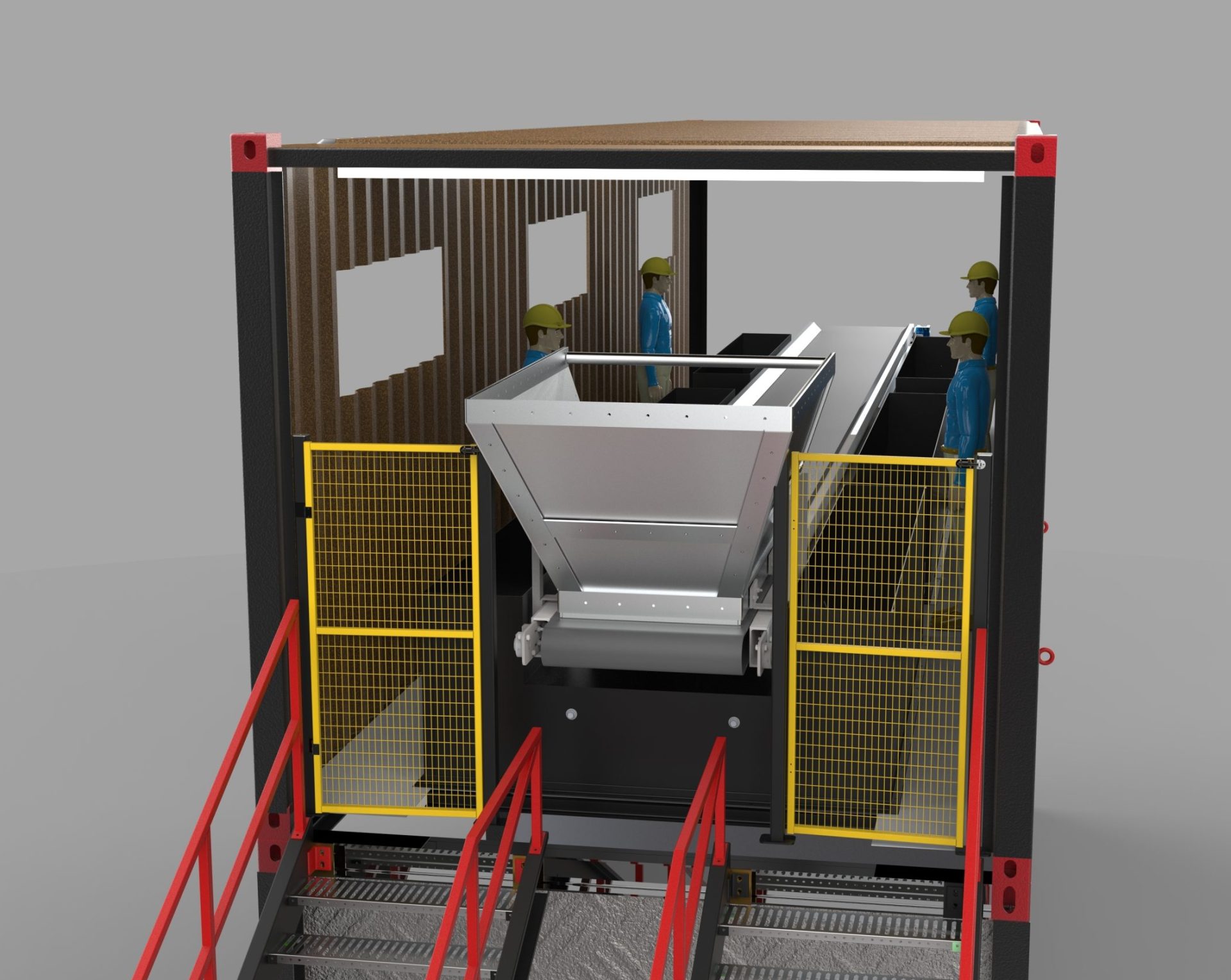

- Automated Sorting Station – Precision-engineered pick points for removing rocks, wood, paper, and contaminants.

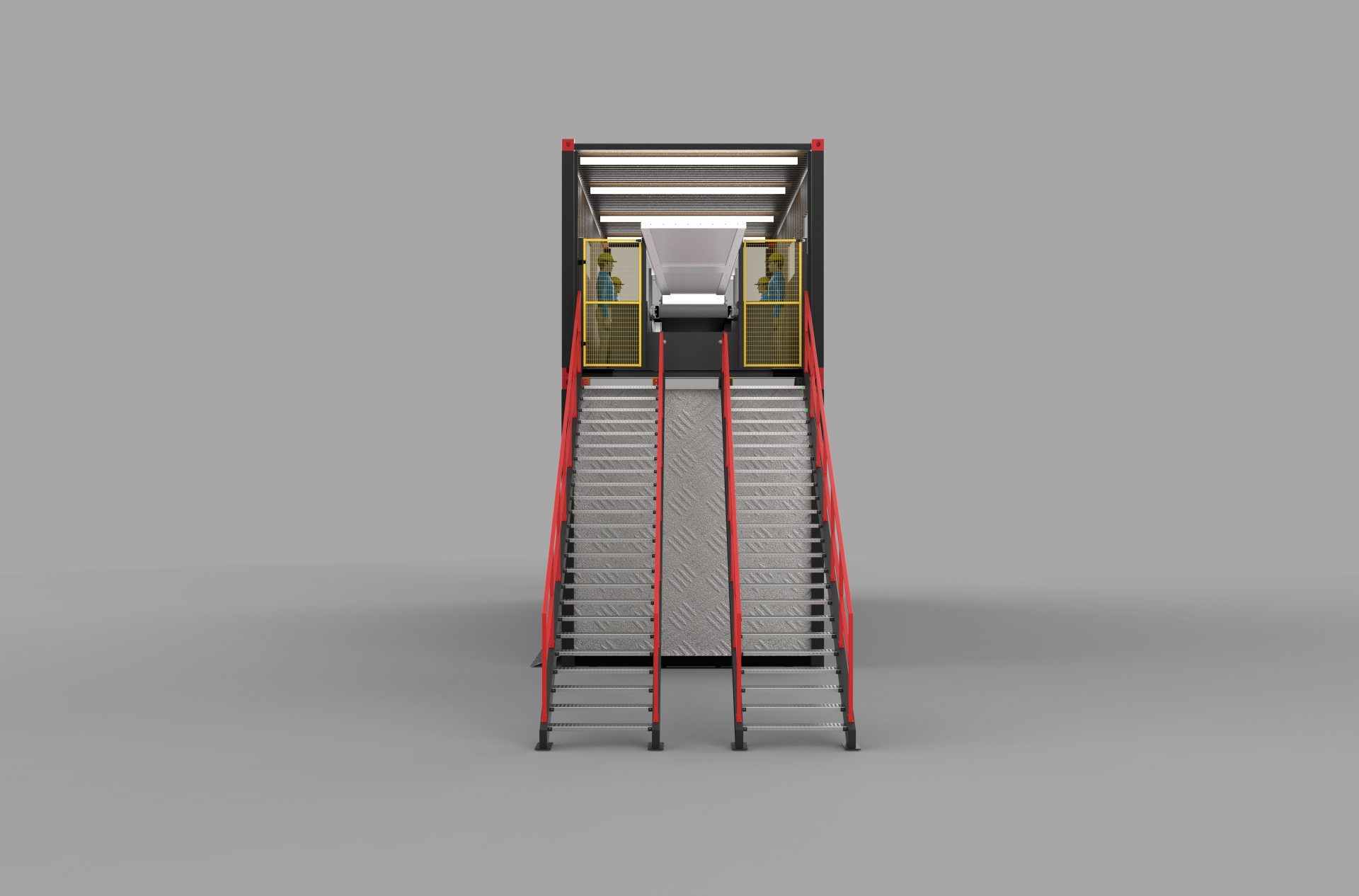

- Integrated Conveyor Network – Synchronized belt system for efficient material transport, staging, and diversion.

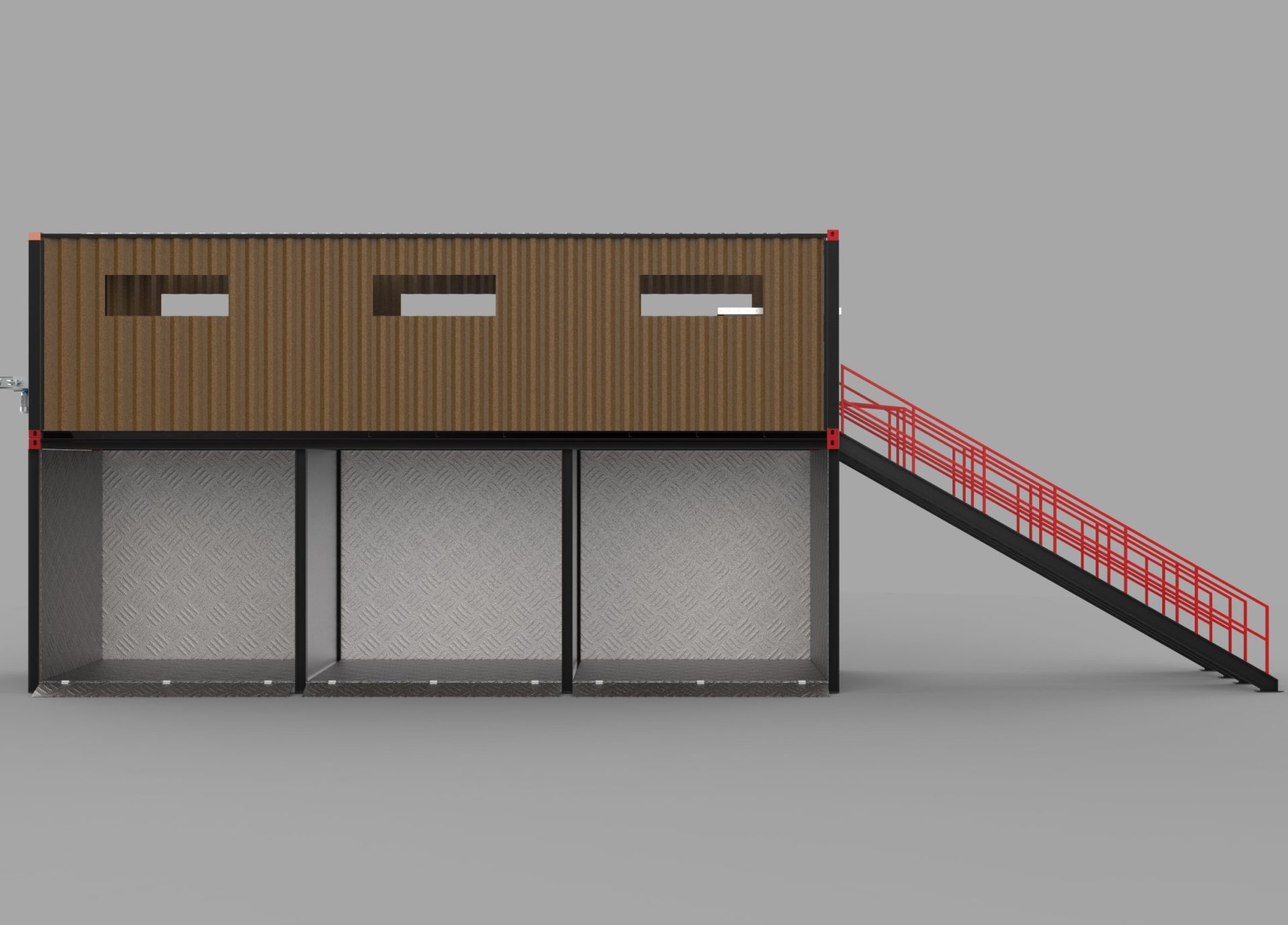

- Ergonomic Operator Design – Safe access platforms, stairs, and bays to minimize manual handling and maximize safety.

- High-Purity Output– System designed to consistently produce specification-grade recycled aggregate.

- Optimized Plant Throughput– Layout and automation logic engineered to maximize processing speed and reduce downtime.

The Design & Implementation Process

- Waste Stream Analysis – Assessing material composition and flow to define sorting requirements and capacity.

- Mechanical & Systems Design – Designing the sorting mechanisms, conveyor layout, and structural supports.

- Safety & Ergonomics Integration – Incorporating platforms, guardrails, and operator zones into the layout.

- Documentation & Handoff – Delivering detailed plant layout drawings, assembly specs, and integration guides.

The Problem. The Fix. The Win.

| The Problem | The Fix | The Win |

|---|---|---|

| Slow, expensive manual sorting | Automated high-speed pick station | More output, lower labour cost |

| Chaotic plant layout causing bottlenecks | Optimized conveyor flow & logical station layout | Smooth operation, higher daily volume |

| Dangerous conditions for workers | Ergonomic platforms, stairs & safe work zones | Safer team, fewer incidents, less risk |

| Low-quality product with contaminants | Precision sorting for purity | Clean, premium aggregate that sells for more |

The Outcome

An automated plant that turns waste into revenue

- Increased Profitability – Higher throughput and lower labor costs directly improved the plant’s bottom line.

- Marketable Output Quality – Consistently clean aggregate allowed the client to command a premium price.

- A Safer, More Efficient Worksite – Ergonomic design reduced incident risk and improved operator morale.