Facing Engineering Challenges?

Our Approach to Overcoming Design and Production Obstacles

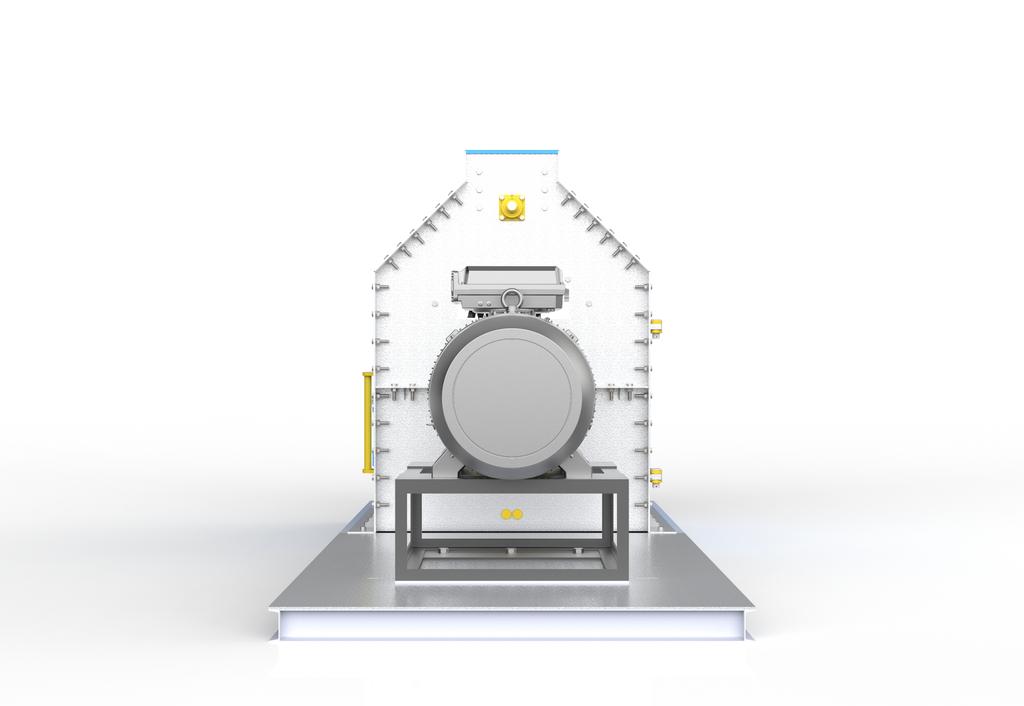

We encountered key challenges during the development of the Advanced Grass Hammer Mill Machine and overcame them with efficient solutions:

Transform grass, hay, and biomass into uniform particles for composting, feed, and biofuel — continuously and reliably.

| Challenge | Our Solution | Result |

|---|---|---|

| Fibrous material wrapping | Integrated directional airflow into the rotor chamber | Zero clogging, consistent feed |

| Particle size inflexibility | Quick-swap screen system with tool-free adjustment | 5-minute changeover for different outputs |

| High-wear environment | Carbide hammer tips and hardened steel liners | 3x longer lifespan than standard mills |

This isn’t just another mill — it’s a reliability upgrade.

✅ 35% higher throughput

✅ Near-zero downtime

✅ Ready for mass production

Designed for farmers, biomass processors, and industrial operators who value uptime over upkeep.