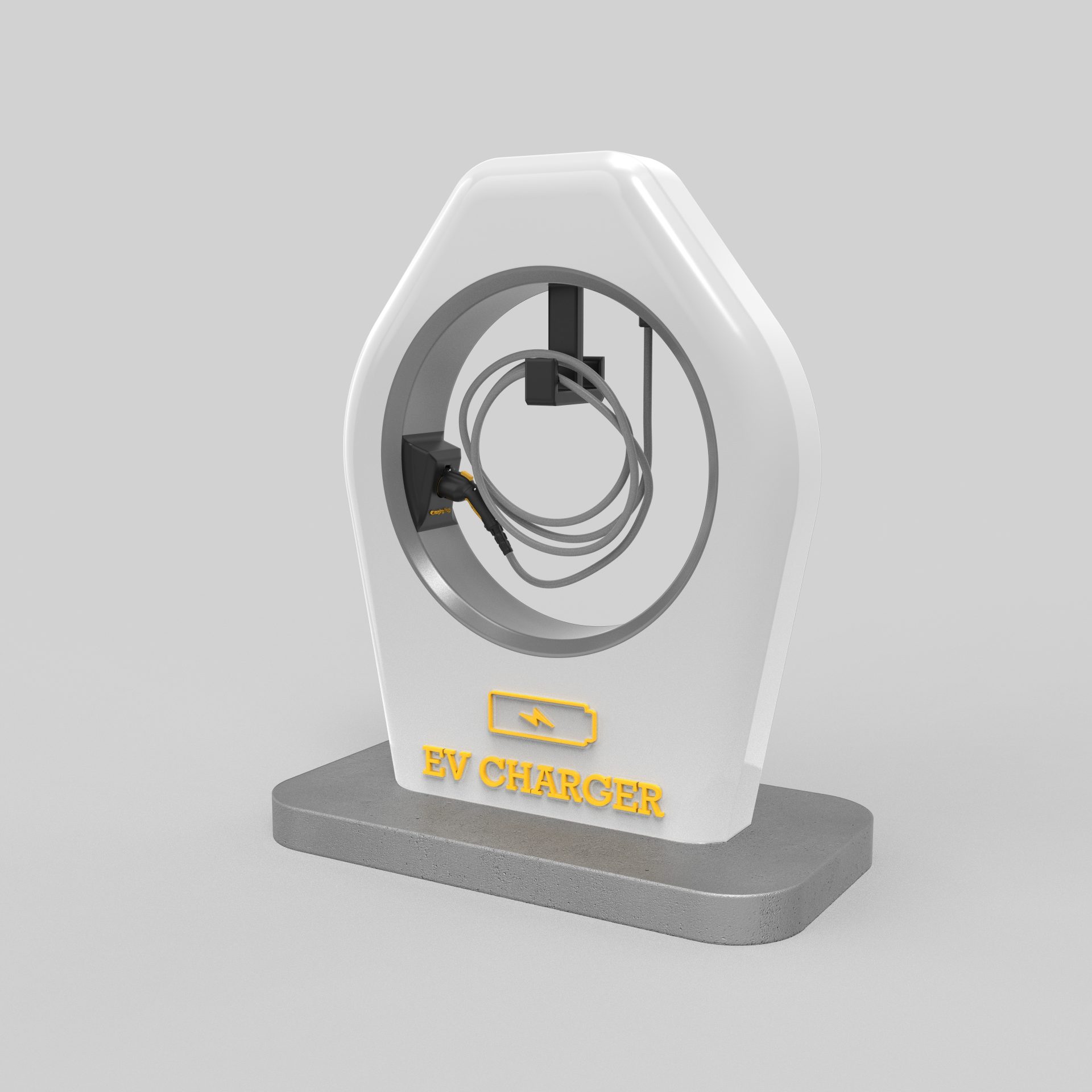

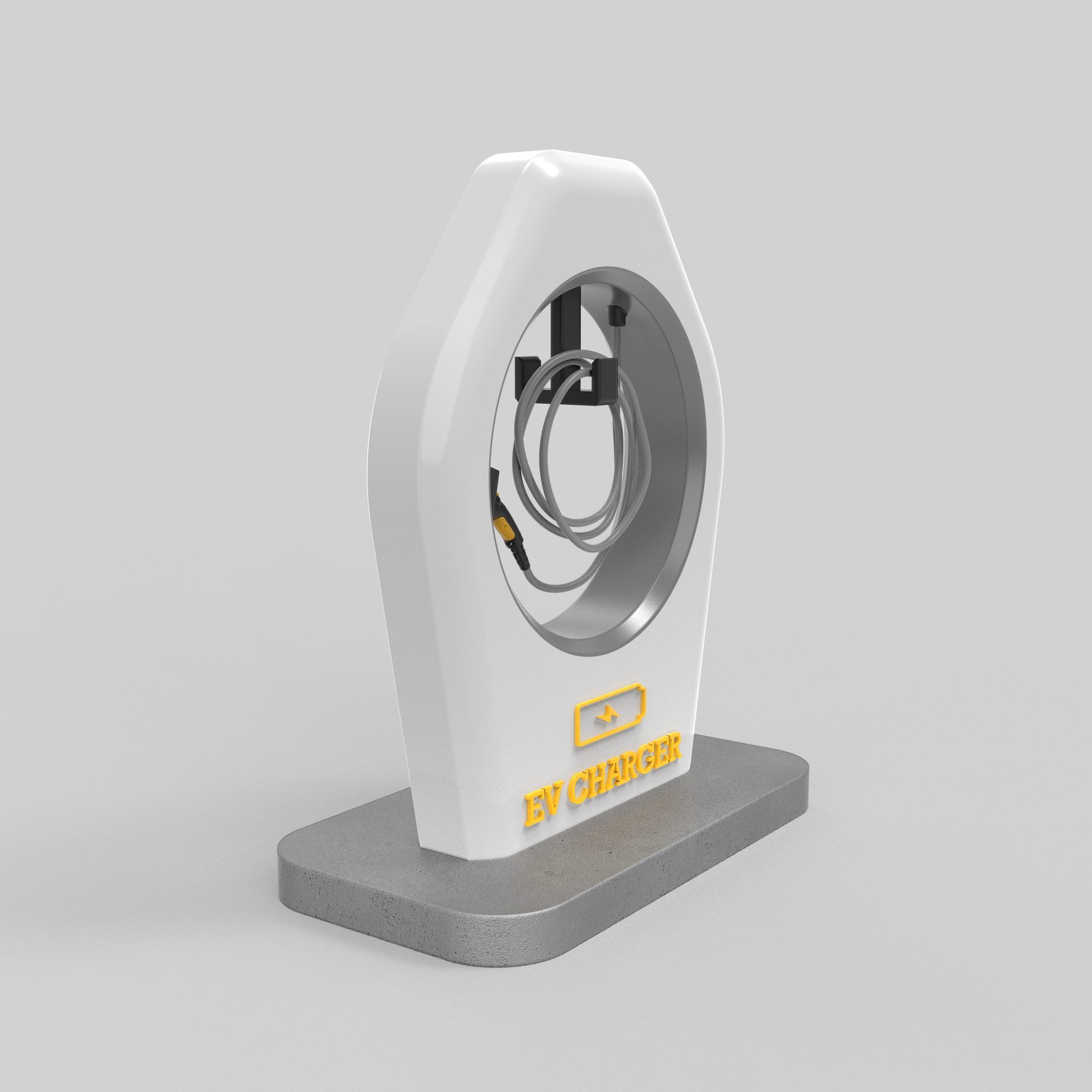

Industrial EV Charger Enclosure

Engineered for

Durability, Precision, and Scalable Production.

A fully designed, manufacturable enclosure system—from structural skeleton to concrete base mold—built to protect charging hardware in any environment.

The Core Build

- Structural Skeleton – Welded rectangular pipe frame with reinforced flanges for rock-solid mounting.

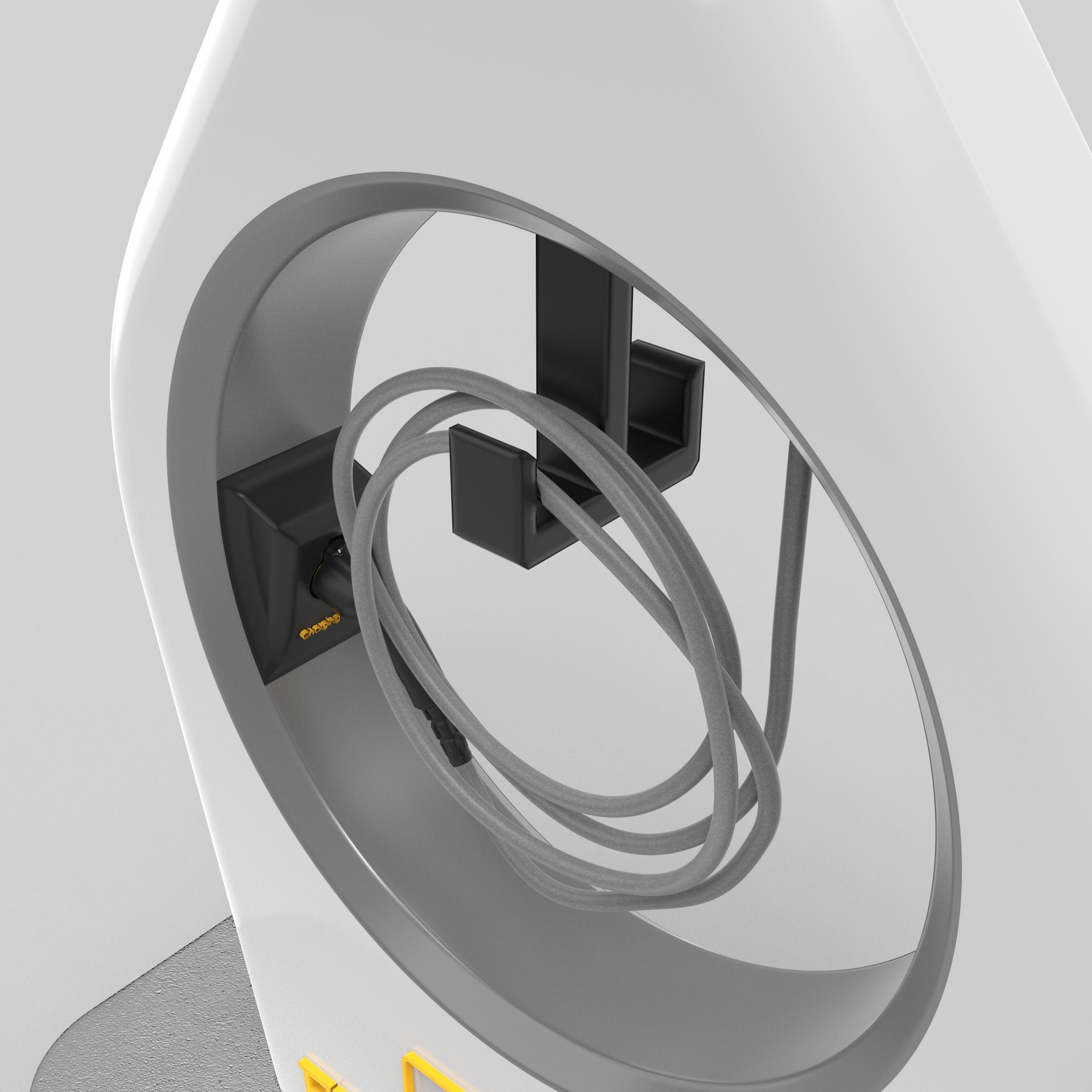

- Precision Sheet Metal – Front, back, and circular panels with laser-cut holes and pressed bends for perfect alignment.

- Integrated Concrete Base – Custom plastic mold design for casting a permanent, stable foundation with integrated conduit.

- Designed for Assembly – All components feature M10 bolt patterns for straightforward, tooled assembly.

- Production-Ready Design – Optimised for laser cutting, sheet metal press, welding, and casting processes.

- Concept & Structural Design

Defining the load-bearing skeleton and interface with the concrete base. - Component Design for Manufacturing

Designing each sheet metal part (Front, Back, Circular Ring) with precise bend allowances and fastener locations. - Mold Engineering

Creating a two-part, keyed plastic mold for the concrete base, including a pipe conduit for cable routing. - Assembly & Validation

Producing assembly drawings, exploded views, and specifying all fasteners (M10 Hex Bolts) for production.

The Development Process

Key Engineering & Manufacturing Solutions

| Challenge | Our Solution | Result |

| Creating a rigid, weather-resistant structure | Welded stainless steel skeleton with gusseted base flanges. | An industrial-grade frame that withstands torsion and environmental stress. |

| Ensuring panel alignment and serviceability | Precision laser-cut holes and extended flanges on all sheet metal components. | Perfect fit-up and easy disassembly for maintenance. |

| Integrating a permanent, grounded base | A custom, re-usable plastic mold for casting a concrete pedestal with conduit. | A stable, low-cost foundation with built-in cable management. |

| Designing for cost-effective, scalable production | Design optimized for standard processes: laser cutting, press braking, welding. | Streamlined manufacturing with multiple sourcing options (U.S. suppliers identified). |

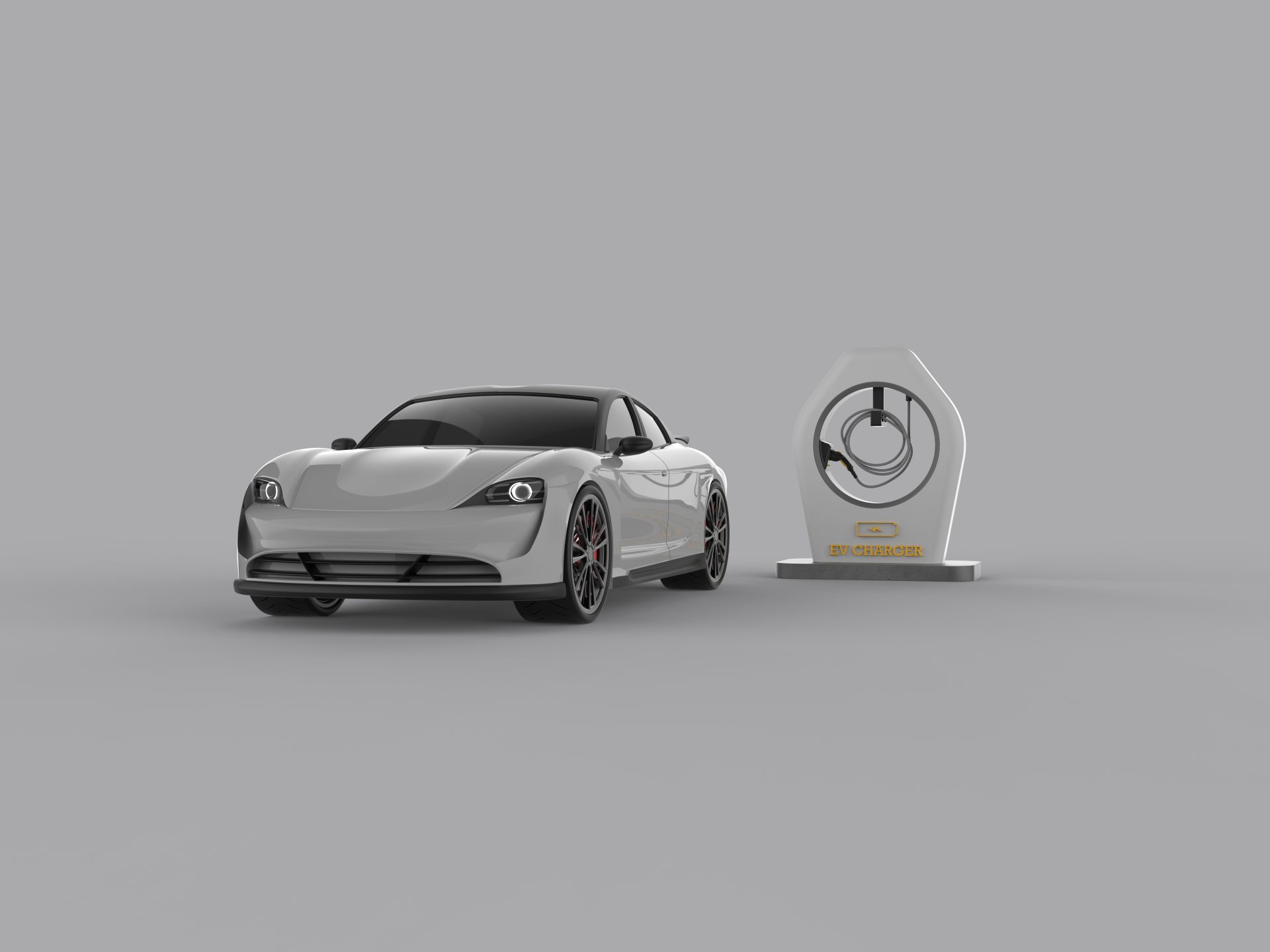

The Outcome

A rugged, install-ready product system.

✅ Weatherproof & Vandal-Resistant – Durable stainless steel and concrete base design ensures long-term outdoor performance.

✅ Streamlined Assembly & Installation – Modular design and detailed instructions reduce on-site labor time and cost.

✅ A Professional Market Presence – Sleek, industrial design builds trust and brand authority in the EV space.