Facing Engineering Challenges?

Our Approach to Overcoming Design and Production Obstacles

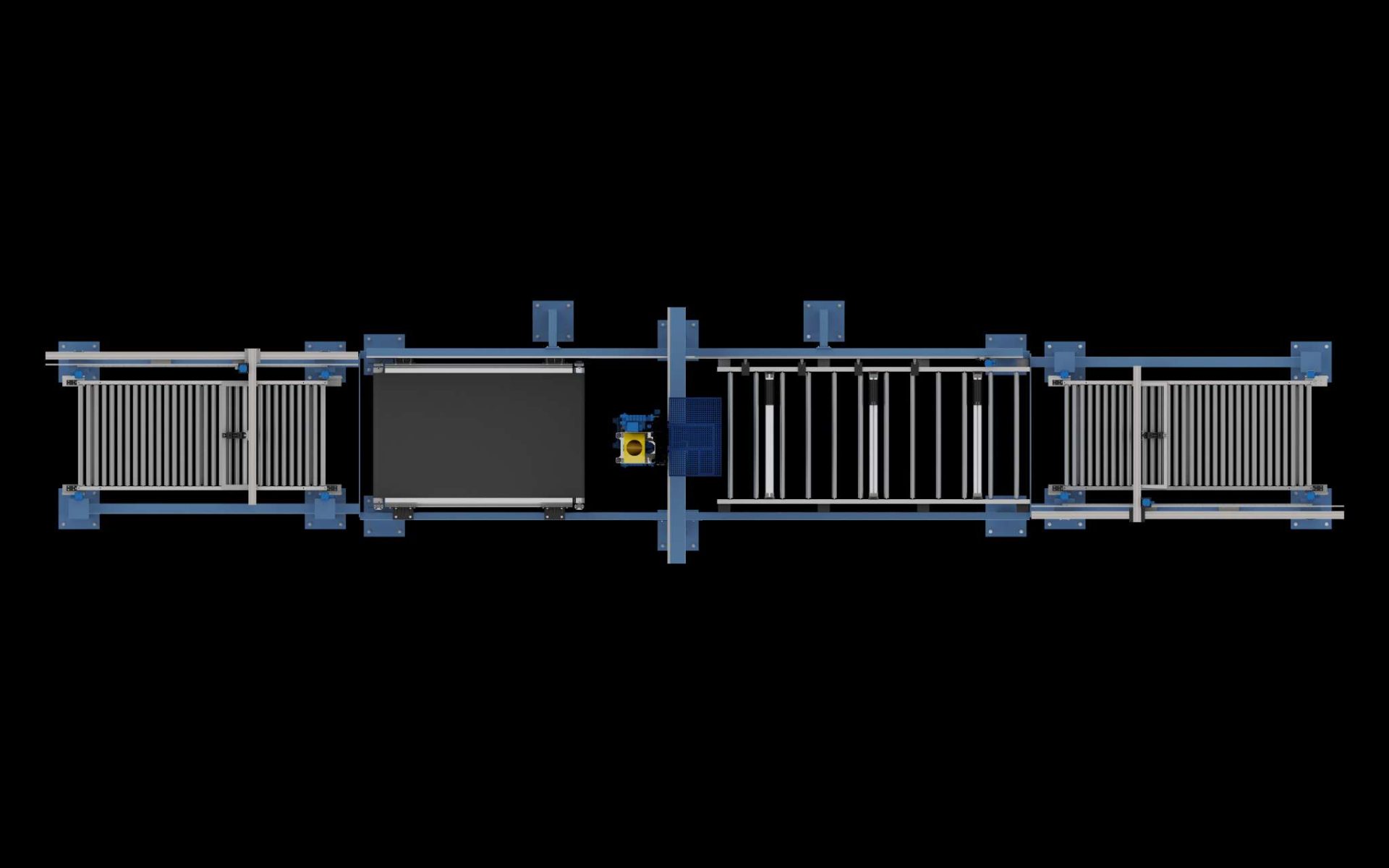

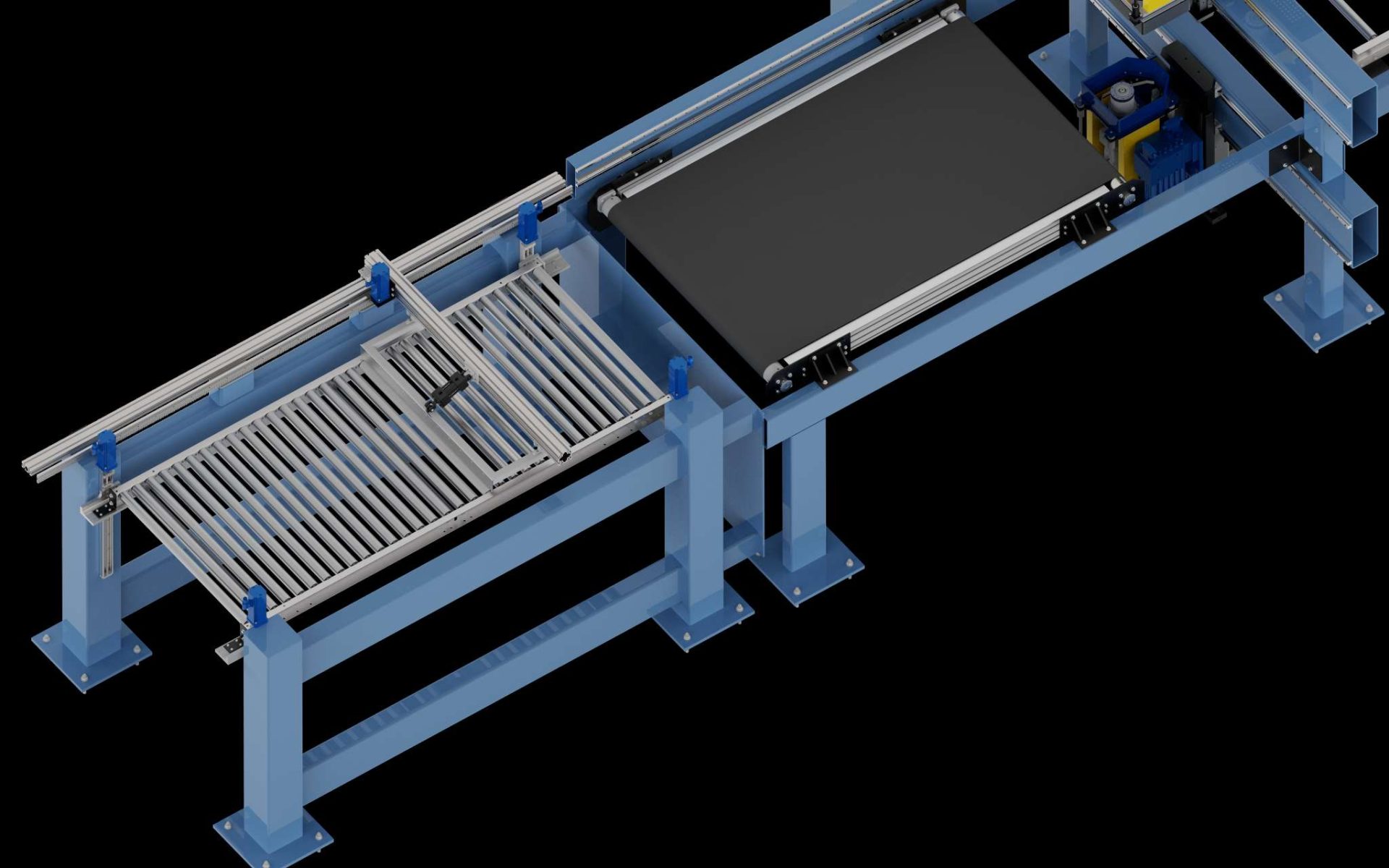

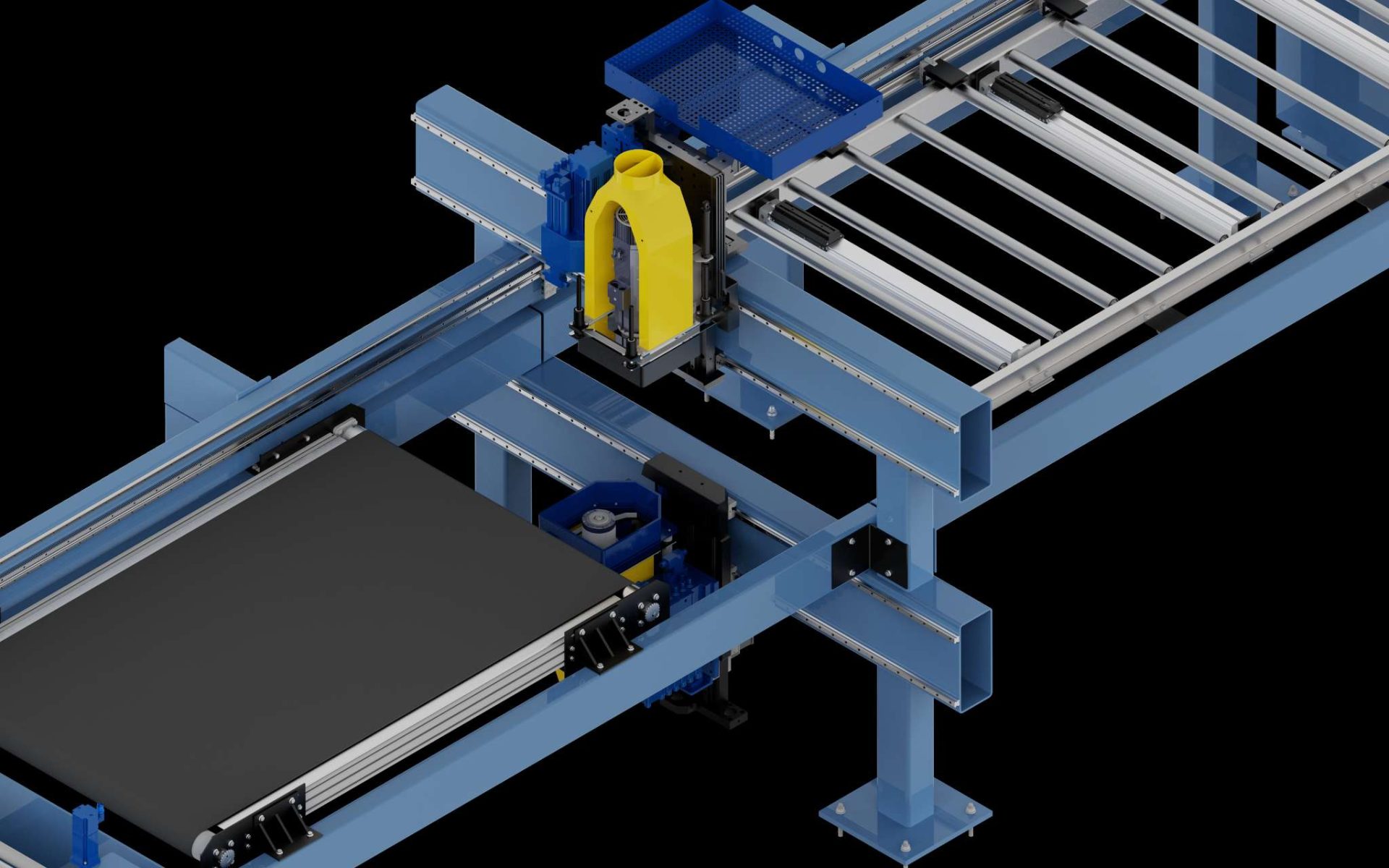

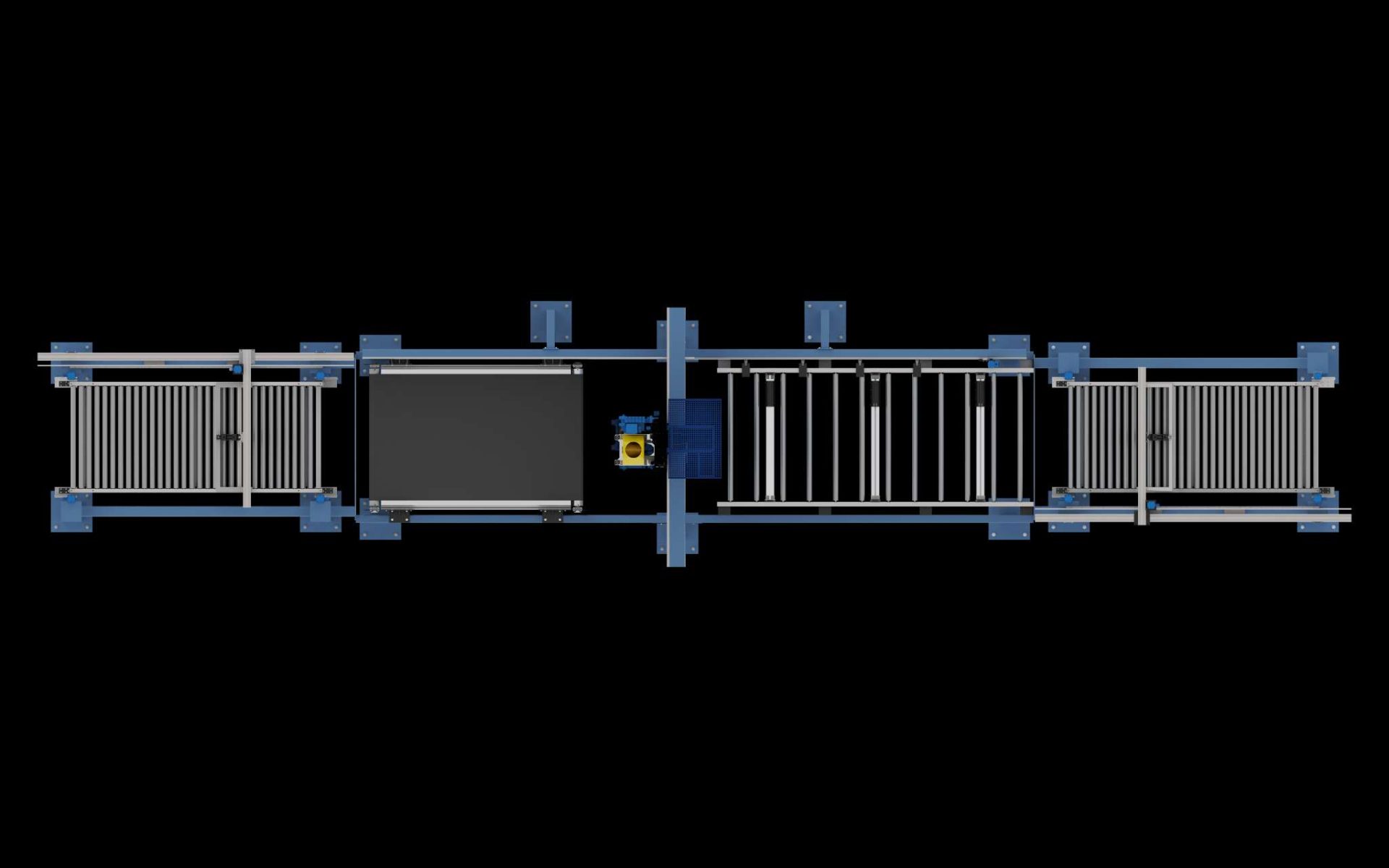

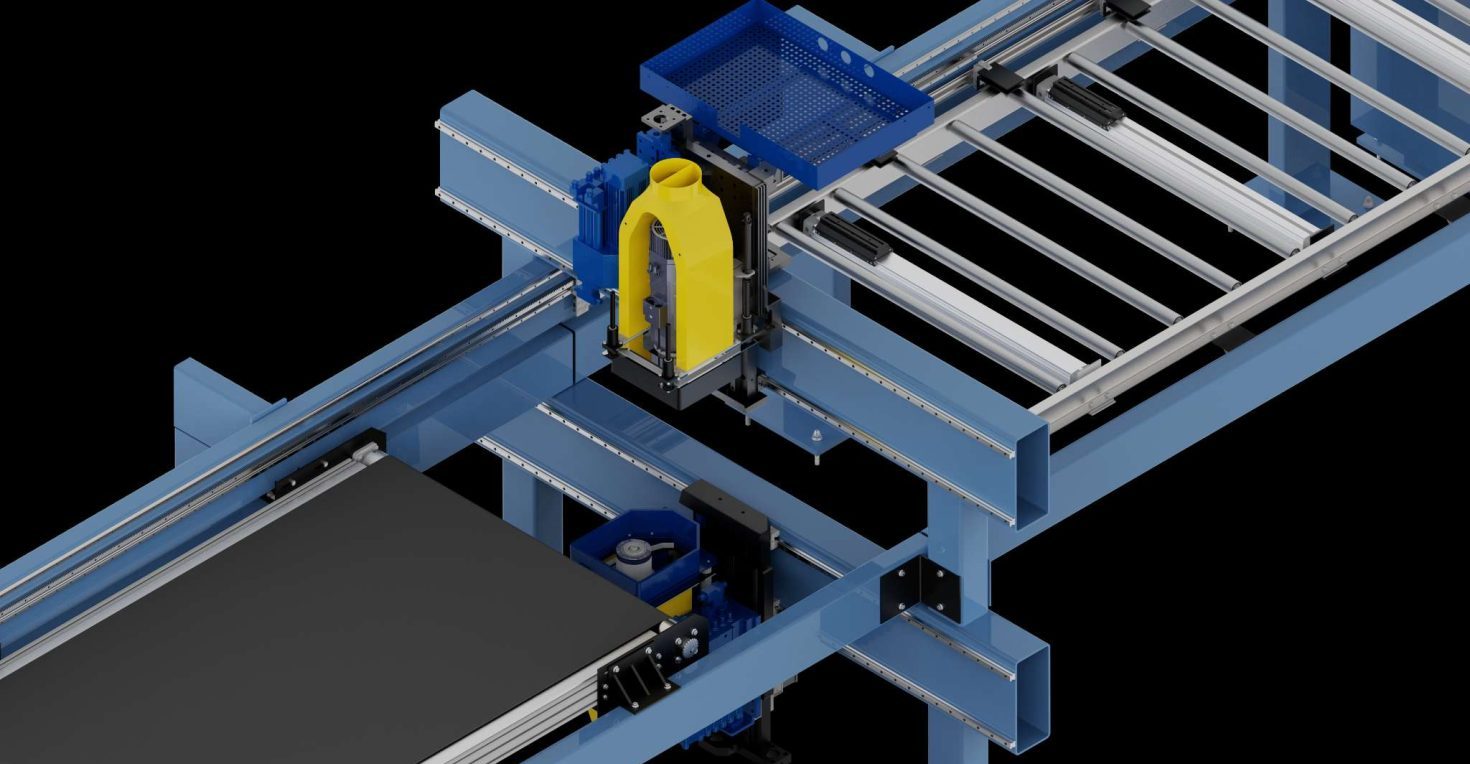

We faced critical challenges while developing the automated aluminum hinge production system — from achieving precise cuts to ensuring cost-efficient scalability. Through a combination of engineering innovation and automation, we successfully overcame these obstacles to deliver a reliable and high-performance manufacturing solution.