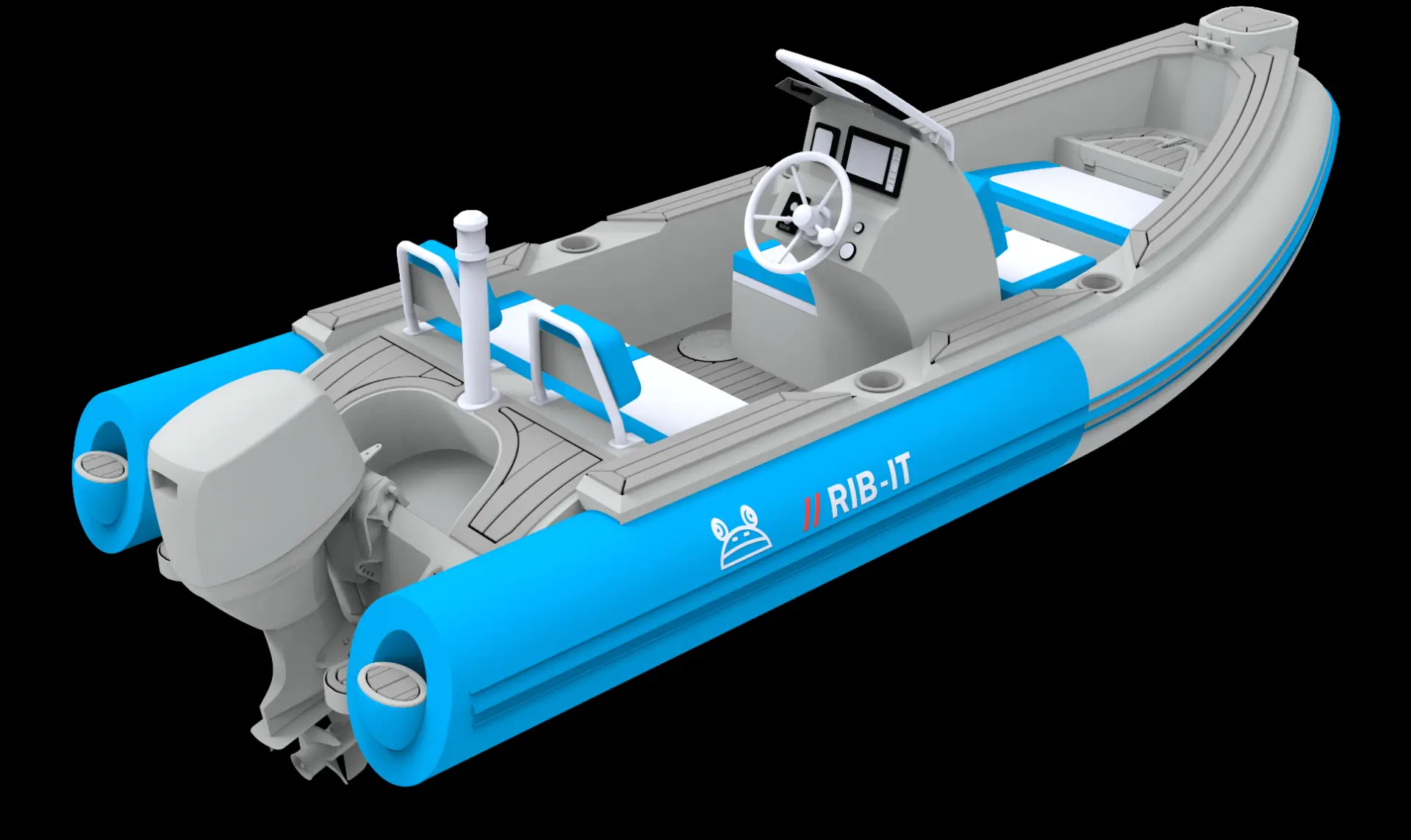

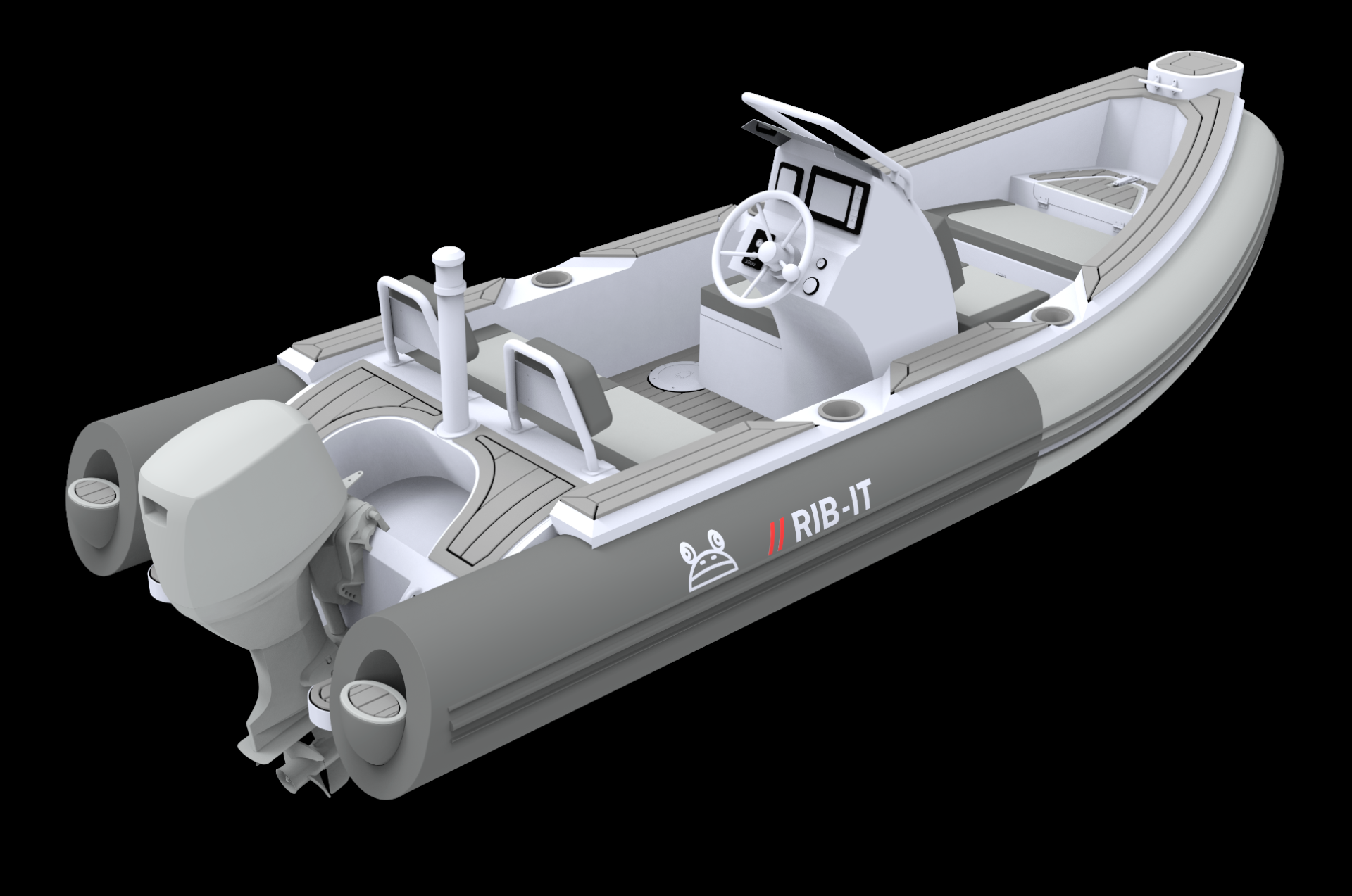

Customizable Rigid Inflatable Boat

From client sketches to photorealistic showcase — ready for online drag-and-drop configuration.

We have provided long-term & extensive designing and rendering services to a USA based customizable RIB boat builder. With sizes ranging from 9 ft to 40 ft, we adapt base aluminium hulls to each customer’s layout and color scheme. Between orders, we convert these models into lightweight visual assets that power an interactive web configurator, giving users a seamless drag-and-drop way to visualize their dream craft.

The Core Innovation

- Parametric CAD Platform – A configurable boat design system that supports multiple lengths and shared architecture across the model range.

- Option Modules Library – Standardized assemblies for consoles, seating, storage, rails, and accessories to enable controlled customization.

- Production Documentation Set – Assembly structure, drawings, and manufacturing-ready outputs for internal build workflow.

- Configurator / Sales Assets – Consistent 3D visuals and view sets aligned to the “build in 3D” purchase flow.

- Material / System Constraints Captured – Design rules aligned to aluminium hull + Hypalon tube construction.

The Core Innovation

- Requirements & Configuration Map

Defined the customization boundaries and option matrix across the 11–28 ft lineup (what is fixed vs configurable). - Master CAD Architecture

Built a top-down assembly structure (hull → deck → modules) to keep variants consistent and manageable. - Module Design + Interfaces

Created option modules with controlled interfaces (mount patterns, clearances, routing space) so variants remain buildable. - Drawing Package + Handoff

Prepared manufacturing/assembly outputs and a repeatable update process for new options or revisions.

Solving Key Challenges

| Challenge | Our Solution | Result |

|---|---|---|

| Managing many customer configurations without creating one-off CAD work. | A parametric master model + standardized option modules with fixed interfaces. | Faster iteration and repeatable outputs across variants. |

| Keeping sales visuals consistent with what production can actually build. | A defined option matrix and CAD-driven view templates aligned to the online “build in 3D” flow. | Clearer communication and fewer specification mismatches. |

| Maintaining manufacturability while scaling the model range. | Captured manufacturing constraints and enforced them through the CAD architecture. | Documentation stays stable as the line expands. |

The Outcome

A modular CAD platform that supports RIB-IT’s custom aluminium RIB line-up and their 3D build/quote workflow.

✅ Parametric model architecture for the 11–28 ft range

✅ Option module library (controlled, repeatable customization)

✅ Drawing + assembly documentation for production handoff

✅ Consistent 3D visuals aligned to the online configurator flow